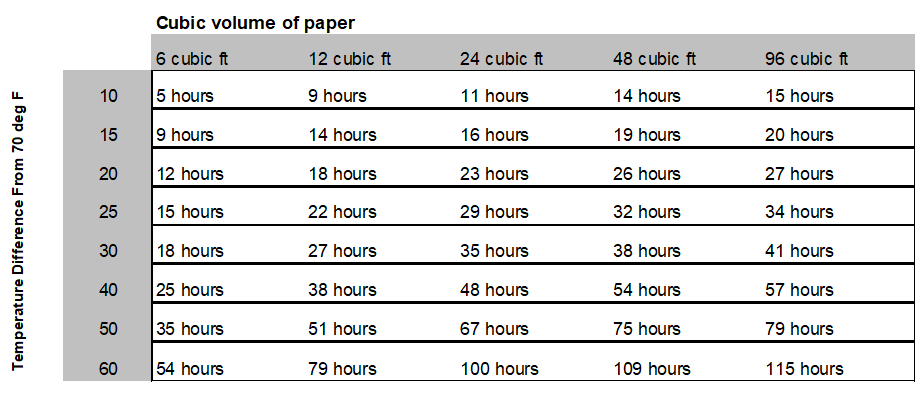

The chart above indicates reasonable times to acclimate paper to the pressroom’s temperature prior to unwrapping the product for printing. Extremes in relative humidity may cause paper to curl or develop tight or wavy edges, depending on whether the relative humidity is high or low. Monadnock Paper Mills will not accept responsibility for these problems when the pressroom relative humidity is below 35% or above 60%.

* Determine cubic volume of paper by multiplying length x width x height [in inches] and dividing by 1,728.

* * The difference between the pressroom temperature and the paper temperature on arrival.

For calculation you may compare the outdoor temperature with the temperature of the room in which the paper will be opened. The times are the number of hours the paper should stand unopened for its temperature to come into balance with press-room temperature.